Newest Urethane Systems Innovations:

New Urethane SystemsUrethane Elastomer Systems

Polyurethanes at Anderson Development Company

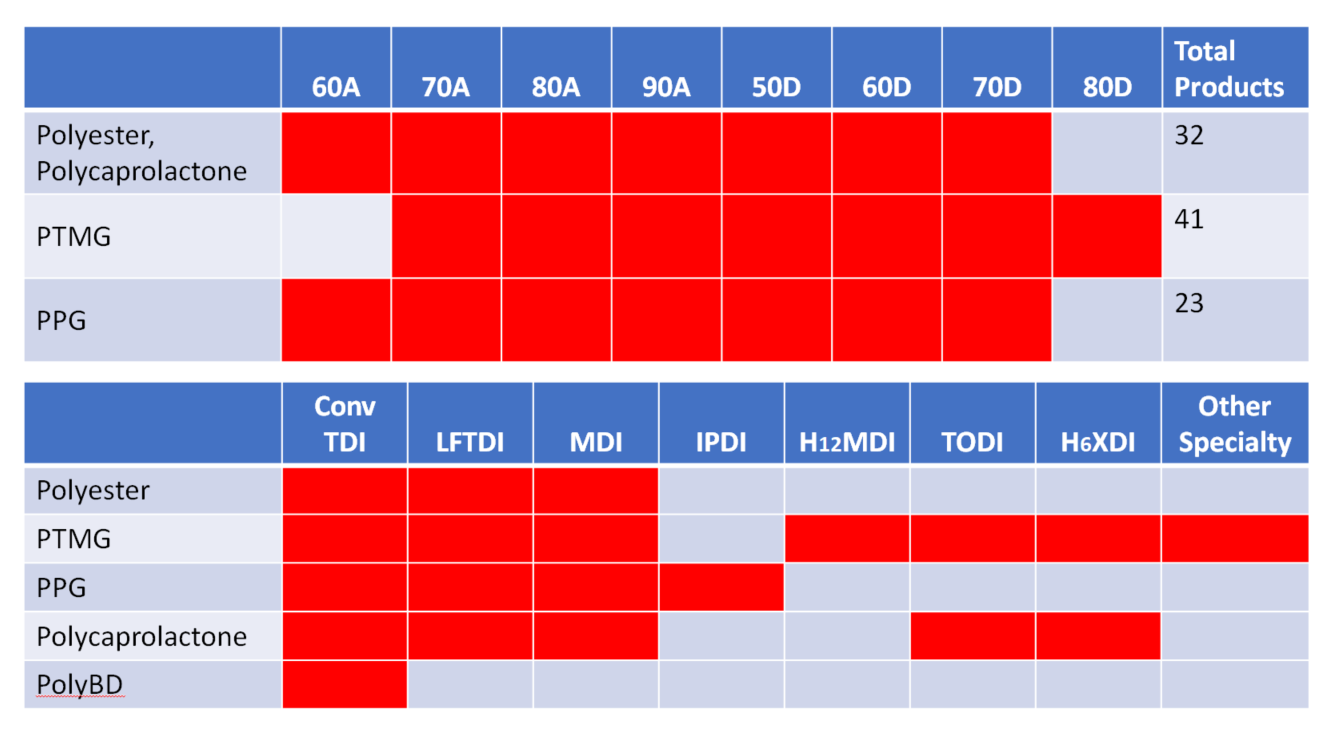

Anderson Development Company (ADC) is an industry leader in polyurethane chemistry for the hot cast market. With over 150 years of combined experience across the technical and sales teams, ADC brings a wealth of experience to problem solving. Due to our extensive customer focus and desire to provide solutions to problems, we are constantly updating our product portfolio with new products including conventional TDI, low free TDI, MDI, and aliphatic systems.Finding Your Solution

If you are interested to know if ADC can meet your challenge, the Physical Data Search Tool is a great place to start. The tool allows the selection of a backbone, property, or curative to find the ADC systems that meet your criteria. If you don’t happen to find what you are looking for, or want to discuss your opportunity further, our technical and sales teams are always happy to work with you to find a solution in our existing products, or even customize a solution for your specific need. Many attributes can be optimized such as pot life, demold time, grindability, viscosity, hardness, physical state (liquid vs. solid), resiliency, and compression set, A:B ratio, viscosity, and physical properties.

Other Capabilities

From one quart to a couple of drums, our R&D and pilot plant facilities can cover any sample size needed. We also can make prototype parts in our applications lab which houses a large vortex mixer, two large ovens, and a large hot table. Our team is knowledgeable and experienced in many different casting techniques either by hand or machine, and we can help your company succeed in casting difficult parts. We can also analyze and identify unknown urethane materials you may want to know about or mimic. Many times we will analyze known parts that maybe have failed in the field and do some failure analysis. Quite often a stoichiometric problem is found that is simple to determine by doing X-ray fluorescence on the part. We can perform a wide spectrum of physical testing including dynamic mechanical analysis (DMA), thermomechanical analysis (TMA), thermogravimetric analysis (TGA), and rotary drum abrasion. So, if a new opportunity arises, or you just want to change a good product into a better product, give us a call.Contact the Urethane Elastomer Systems Team